Power Gear Technology

Power Gear Technology is proud to serve as the official Canadian distributor for KYS Power Transmission Parts, a leading manufacturer with over four decades of experience in foundry operations and power transmission component manufacturing. Since 1985, KYS has been delivering high-quality V-belt pulleys, timing pulleys, taper bushes, and couplings to global markets, backed by our commitment to zero-defect production and technical excellence.

KYS specializes in power and motion transmission components for diverse industries including industrial automation, manufacturing, automotive, and heavy machinery. With their state-of-the-art foundry and manufacturing facility and over 120 employees, they export to more than 40 countries worldwide while maintaining the highest standards for precision and reliability in every component.

Leading manufacturer of power transmission components with 40+ years of foundry expertise, specializing in V-belt pulleys, timing pulleys and taper bushes for industrial automation and manufacturing applications.

Standard vs VTP Pulleys

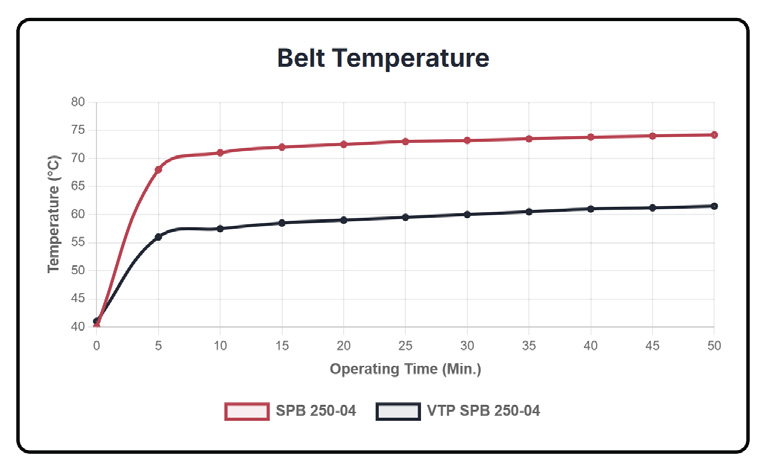

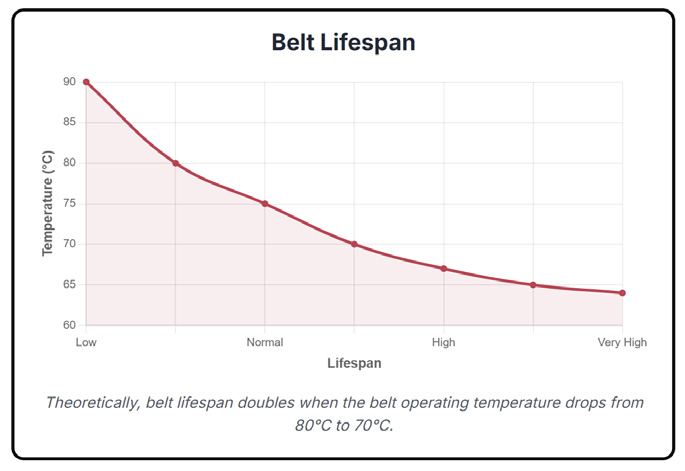

VTP pulleys operate at a temperature 17°C lower than standard models, delivering superior performance and dramatically extending belt life.

Extended belt lifespan through reduced operating temperature

Optimized efficiency through innovative thermal management

Reduced maintenance and replacement costs

Lower energy consumption and environmental impact

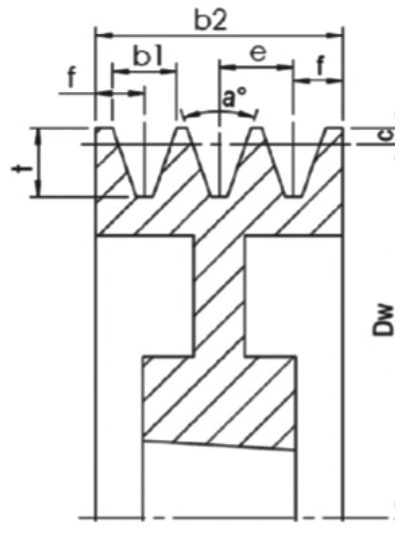

| ZODIAC SIGN SIZE | DN 2221 | DIN 2217 |

VIDA SCREW DIN ISO 5290 |

||||||

|---|---|---|---|---|---|---|---|---|---|

| SPZ/XSPZ | SPA/XSPA | SPB/XSPB | SPC/XSPC | 9N/9J 3V/3VX |

15N/15J 5V/5VX |

25N/25J 8V | |||

| 10 | 13 | 17 | 22 | 25 | 32 | ||||

| PULLEY PROFILES | Z | A | B | C | - | D | - | - | - |

| b1 | 5/13" | 1/2" | 9/14" | 13/15" | 1/1" | 19/15" | 5/14" | 3/5" | 1/1" |

| c | 1/13" | 1/9" | 2/15" | 3/16" | 1/4" | 5/16" | 0/1" | 1/16" | 1/10" |

| e | 7/15" | 7/12" | 3/4" | 1/1" | 8/7" | 16/11" | 2/5" | 11/16" | 9/8" |

| f | 5/16" | 2/5" | 1/2" | 2/3" | 3/4" | 15/16" | 5/14" | 1/2" | 3/4" |

| t | 7/16" | 6/11" | 11/16" | 15/16" | 13/15" | 11/10" | 5/14" | 3/5" | 1/1" |

| a 34° | Dw≤41/13" | Dw≤65/14" | Dw≤112/15" | Dw≤62/5" | Dw≤14/1" | - | - | - | - |

| a 36° | - | - | - | - | - | Dw≤315/16" | Dw≤39/11" | - | - |

| a 38° | Dw>41/13" | Dw>65/14" | Dw>112/15" | Dw>62/5" | Dw>14/1" | Dw>315/16" | Dw≤65/11" | Dw128/13" | Dw≤63/4" |

| a 40° | - | - | - | - | - | - | Dw≤65/11" | Dw≤128/13" | Dw≤63/4" |

| a 42° | - | - | - | - | - | - | Dw189/16" | Dw>63/4" | Dw>353/16" |

The VTP pulley is a next-generation V-belt pulley made from durable GGG 50 material, offering 2.5 times more strength than standard pulleys. It's up to 50% lighter, supports smaller bearings, and simplifies installation, handling, and logistics.

Thanks to their special design, VTP pulleys operate at a temperature 17°C lower than standard models, which significantly increases belt life.

Up to 50% lighter

17°C lower operating temperature

Tension-relieving angled arm design

Compatible with small bearings

Cost advantage in logistics

Material: Durable GGG 50

Weight: Up to 50% lighter than standard

Temperature: 17°C lower operating temperature

Profiles: SPZ, SPA, SPB, SPC series

Strength: 2.5 times more than standard pulleys

Design: Tension-relieving angled arm design

Bearings: Compatible with smaller bearings

Logistics: Cost advantage in transport

Applications: Next-generation V-belt power transmission systems requiring high efficiency, reduced weight, and lower operating temperatures. Ideal for industrial machinery, manufacturing equipment, and high-performance applications where extended belt life and energy efficiency are critical.

Profile: SPZ (narrow V-belt)

Diameter Range: 170mm to 800mm

Grooves: 1 to 6 and 8 grooves available

Bush Types: 1610, 2012, 2517, 3020, 3525

Shaft Range: 14mm to 90mm

Material: High-strength GGG 50

Design: Ventilated turbo structure

Temperature: 17°C cooler operation

Applications: Compact power transmission systems, small to medium industrial machinery, HVAC equipment, and applications requiring narrow belt profiles. Perfect for space-constrained installations with high efficiency requirements.

Profile: SPA (standard A-profile)

Diameter Range: 170mm to 800mm

Grooves: 1 to 6 grooves available

Bush Types: 1610, 2012, 2517, 3020, 3525, 4030

Shaft Range: 14mm to 100mm

Construction: Lightweight ventilated design

Efficiency: Enhanced heat dissipation

Weight: Up to 50% lighter

Applications: General purpose industrial drives, conveyor systems, agricultural machinery, and medium-duty power transmission. Ideal for applications requiring reliable performance with reduced maintenance and extended belt life.

Profile: SPB (standard B-profile)

Diameter Range: 180mm to 1250mm

Grooves: 1 to 6 and 8 grooves available

Bush Types: 1610, 2012, 2517, 3020, 3525, 4030, 4535, 5040

Shaft Range: 14mm to 125mm

Heavy Duty: High torque applications

Cooling: Advanced ventilation design

Durability: Extended service life

Applications: Heavy-duty industrial machinery, mining equipment, large conveyor systems, and high-power transmission applications. Essential for demanding environments requiring maximum reliability and performance.

Profile: SPC (standard C-profile)

Diameter Range: 212mm to 1250mm

Grooves: 3 to 6 and 8 grooves available

Bush Types: 3020, 3525, 3535, 4030, 4040, 4535, 5040

Shaft Range: 25mm to 125mm

Heavy Duty: Maximum power transmission

Performance: Superior heat management

Applications: Industrial heavy machinery

Applications: Extra heavy-duty industrial applications, large manufacturing equipment, steel mills, cement plants, and power generation facilities. Designed for the most demanding power transmission requirements with maximum efficiency and reliability.

Discover the complete portfolio of KYS Power Transmission Parts, belt pulleys, and mechanical components. Find the ideal solution for your industrial automation, manufacturing, or power transmission needs.

View All KYS ProductsOur technical team is ready to help you select the perfect KYS power transmission solution for your application. From standard belt pulleys to custom foundry components, we provide complete support from specification to installation.

Power Gear Technology Inc.

75 rue Principale, Stanstead, Quebec, Canada, J0B 1E0

Phone: 1-438-842-1650

Email: info@powergeartech.com

© 2023 - Power Gear Technology Inc.

We partner with manufacturers that abide by these organization's strict specifications and QC practices.