Power Gear Technology

Power Gear Technology est fier d'être partenaire d'Esco, offrant leurs solutions de 'couplings' avancées à nos précieux clients.

Esco Couplings est un leader mondialement reconnu dans le développement, la conception et la fabrication de 'couplings à engrenages et à disques pour le marché industriel. Avec plus de 60 ans d'expertise, Esco est devenu synonyme de qualité supérieure et d'innovations. Leur engagement dans la R&D garantit que chaque projet bénéficie de la solution idéale, livrée efficacement grâce à leurs sites de production en Belgique, en Chine et en Inde. Soutenu par des filiales et des partenaires à travers le monde, Esco fournit des conseils personnalisés, des prix compétitifs et des délais de livraison exceptionnels.

Leader mondialement reconnu en engrenage et "disc couplings", offrant des solutions industrielles innovantes et de haute qualité.

Visitez le site d'Esco GroupAucune traduction française n'est disponible pour les fiches techniques d'Esco Couplings.

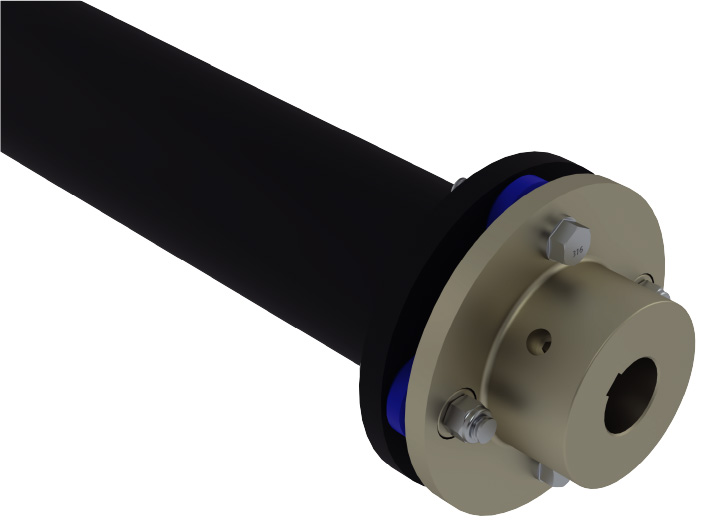

Multicrown gearing

Homogeneous torque transmission

Reduced backlash

Optimum max. torque / max. misalignment ratio

Optimum flange connection

Heavy-duty and industrial applications

Pumps, turbines, generators, compressors

Conveyors and roller conveyors

Cranes and lifting devices

Textile, paper machines, maritime applications

Optimized shaped discs

AISI 301 full hard stainless-steel discs

Optimal power transmission

Designed, calculated, and tested for infinite life

Operation in dirty, corrosive environments

Petrochemicals and industrial applications

Pumps, turbines, generators, compressors

Conveyors, rolling mills

Textile, paper machines, test benches

Maritime applications

Lubrication-free coupling

Light weight

High strength

Chemical resistance

Low coefficient of thermal expansion

Reduced vibrations

Reduced load on bearings

High misalignment capacity

Cooling towers

Low-cost solution

Compact design

For small shaft distances

Dry-running

Easy installation, maintenance-free

Vibration damping

Electrically insulating

Available from stock

General industrial applications

Food industry

Textile industry

Robotics

Logistics

Power Gear Technology Inc.

75 rue Principale, Stanstead, Québec, Canada, J0B 1E0

Téléphone : 1-438-842-1650

Email : info@powergeartech.com

© 2023 - Power Gear Technology Inc.

Nous collaborons avec des fabricants qui respectent les spécifications strictes et les pratiques de contrôle qualité de ces organisations.